we design and deliver end-to-end car seat assembly lines that enable efficient, high-quality, and scalable production of automotive seats. Our systems are tailored to match your model variants, production volume, and ergonomic standards

What We Offer

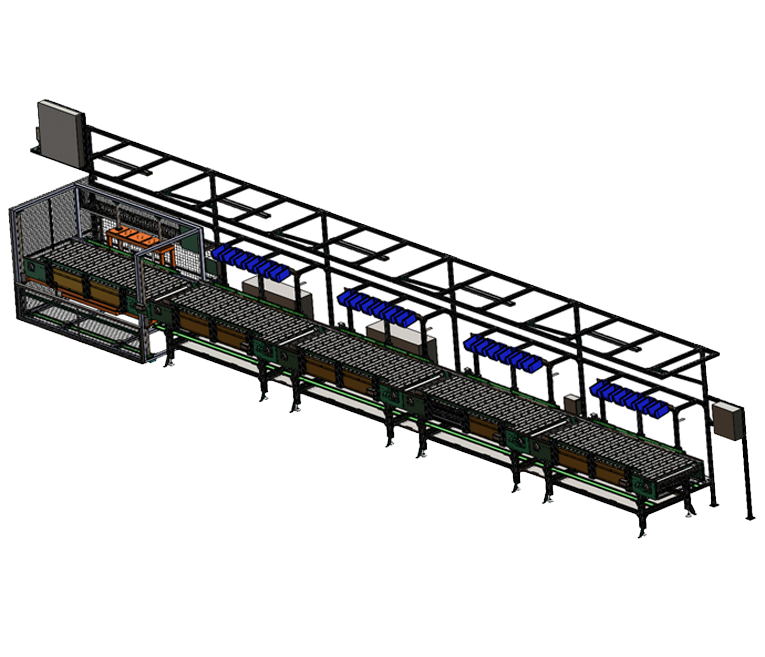

Our car seat assembly solutions integrate mechanical structures, material handling systems, and automated tools into a seamless, operator-friendly production flow. Key offerings include:

-

Manual, Semi-Automatic & Fully Automatic Assembly Lines

Flexible solutions based on your plant’s productivity targets.

-

Conveyorized Workstations

Synchronized stations for frame welding, foam padding, fabric fitting, recliner assembly, and final inspection.

-

Integrated Tooling & Fixtures

Ergonomically designed jigs and fixtures for high repeatability and operator comfort.

-

Testing & Validation Units

On-line torque testing, recliner actuation checks, and load tests to ensure compliance with OEM standards.

Modular & Scalable Designs

Our modular layout allows easy scaling for new models or increased capacity—supporting both Just-in-Time (JIT) and Just-in-Sequence (JIS) manufacturing strategies.

Typical Assembly Processes Covered

-

Frame and recliner sub-assembly

-

Foam and trim cover fitting

-

Headrest, armrest, and track mounting

-

Electrical component installation (e.g., seat heaters, sensors)

-

Functional testing and final quality check

-

Barcode-based traceability integration (optional)

Industries & Clients We Serve

-

Automotive OEMs

-

Tier-1 Seating Manufacturers

-

Commercial Vehicle Assembly Plants

-

EV & Premium Vehicle Seat Suppliers