Mixer – Downstream Line

Once rubber is mixed in an internal mixer (like Banbury or Intermix), the downstream line handles the discharge, cooling, forming, and stacking of the rubber compound. It prepares the material for further processing or storage.

Mill (for sheeting)

-

Function

Processes the rubber compound into sheets of uniform thickness before feeding into batch-off.

-

Often used after mixer discharge, especially in two-stage mixing. Conveyor System

-

Function

Transports hot rubber from mixer discharge or open mill to the batch-off

-

Types

Inclined, horizontal, cooling conveyors.

Mill to mill conveyor

-

Source

opening Mixing (Dump mill)

-

Material handling

Sheet transferred (Belt Conveyor)

-

Function

Transfers hot rubber sheet from the Dum mill to the Sheet Mill.

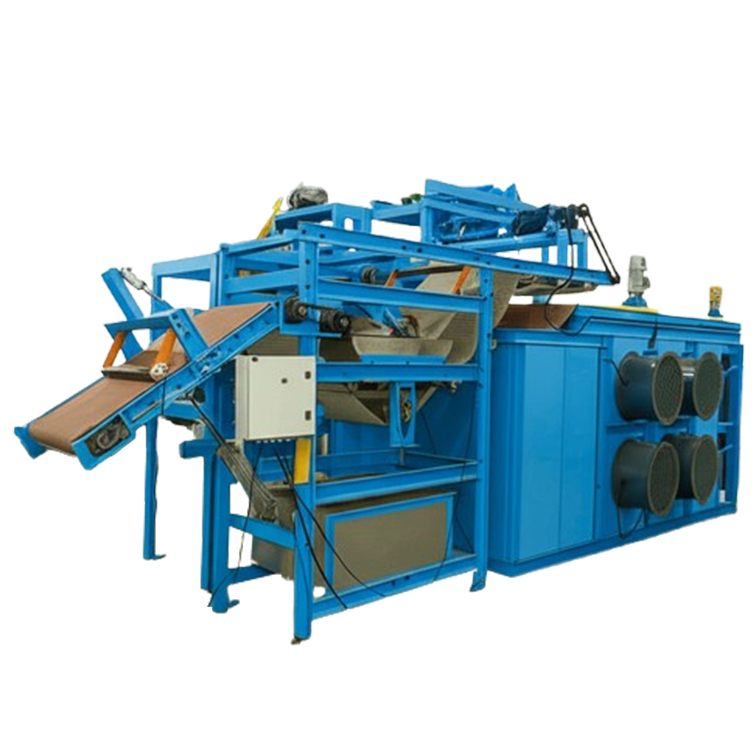

Batch-off System Function

Cools and stacks the hot rubber sheets, and it contains

Inlet Conveyor (Hot Sheet Entry)

-

Source

Open mixing mill or sheeter.

-

Material handling

Heat-resistant rubber or metal belt.

-

Function

- Transfers hot rubber sheet (~100–130°C)

- Guides the sheet into the dip tank at a controlled speed.

-

Safety Features

Guards, emergency stops, temperature sensors.

Number Punching / Marking Unit (Optional but valuable)

-

Timing

Before or after dip tank (usually before).

-

Function

Embeds or marks batch number, mix code, or timestamp on the sheet.

- Manual stamp press

- Pneumatic number punching

- Hot stamping or inkjet marking (for advanced traceability).

-

Purpose

Enables batch traceability, QA, and audit

Dip Tank – Anti-Tack Application

-

Rubber Sheet Entry

The hot rubber sheet enters from the inlet conveyor or mill output.

-

Guided Submersion

The sheet passes over guide rollers into the dip tank where it is partially or fully submerged in the anti-tack solution.

- Dip depth can be adjusted.

- Anti-tack can be sprayed additionally at the surface.

- Roller Support: Immersion rollers maintain the path of the rubber sheet underwater to ensure uniform coating.

-

Squeeze Section

Exiting the tank, the rubber sheet passes between squeeze rollers

- Removes excess solution.

- Ensures consistent application thickness.

- Prevents dripping onto the cooling conveyor.

- Solution Recycling: Excess solution drips into a collection tray and is optionally filtered and recycled back to the dip tank.

-

Safety Features

Guards, emergency stops, temperature sensors.

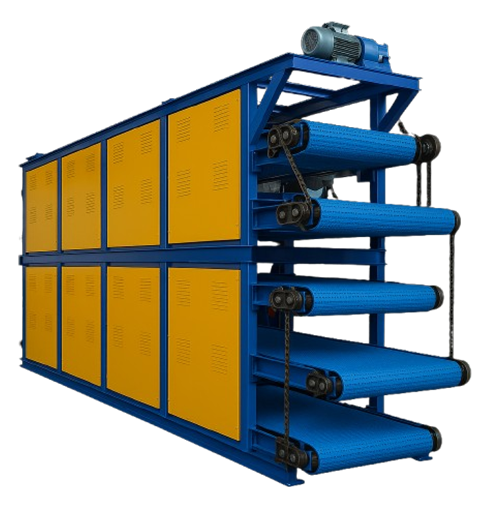

Cooling Conveyor / Cooling Chamber

-

Length

Typically, 3–6 meters based on plant capacity.

-

Features

- Forced-air cooling via axial or radial fans.

- Optional water mist or chilled air system.

-

Sheet Temperature

Reduced to ~40–50°C.

-

Sheet Flow

Controlled to maintain tension-free movement.

Drying Zone

-

Combined with cooling conveyor.

-

Fans remove moisture from anti-tack liquid.

-

Optional Add-on

Infrared drying lamps for faster evaporation.

Cutter or Continuous Sheet Mode (Optional)

-

Function

Cuts sheet to programmable length.

-

Guillotine with pneumatic/hydraulic actuation.

Festooning Unit OR Stacking Conveyor

-

Festooning

- Sheet is hung over rods in a zigzag loop.

- Suited for long, continuous sheets.

-

Stacking

- Rubber sheet is cut and neatly stacked on trays/pallets.

- Tray moves down automatically based on sheet height.

-

Features

- Servo/PLC control for accuracy.

- Batch counters and sensors.

Exit Conveyor / Pallet Transfer

-

Moves finished batches to storage or weighing station.

-

Can be linked with weighing scales or robotic palletizing for large units.

Strip Cutter / Sheet feeder Cutter (optional)

-

Function

Cuts rubber into desired sizes for storage or further processing.

Metal Detector (optional)

-

Function:

Detects metallic contamination in the rubber sheet before final packaging or storage.

Output Recording System (Weighing & Labeling)

-

Function

Automatically weighs each batch and prints labels with batch ID and weight.

Process Flow Summary

-

Mixer discharges rubber.

-

Rubber moves to open mill or conveyor (if sheeting required).

-

Rubber sheet enters batch-off system.

-

Sheet is cooled, dried, and stacked/festooned.

-

Batches are stored or moved to next production stage.

Purpose & Benefits

-

Ensures safe handling of hot rubber.

-

Allows for cooling and anti-tack treatment.

-

Facilitates batch identification and traceability.

-

Prepares material for storage or calendaring/extrusion.