Material Transfer & Feeding Solutions

Jumbo Bag Unloading Systems

-

Best suited for material consumption below 1 ton/hour

-

Simple and cost-effective bulk transfer of fillers and carbon black

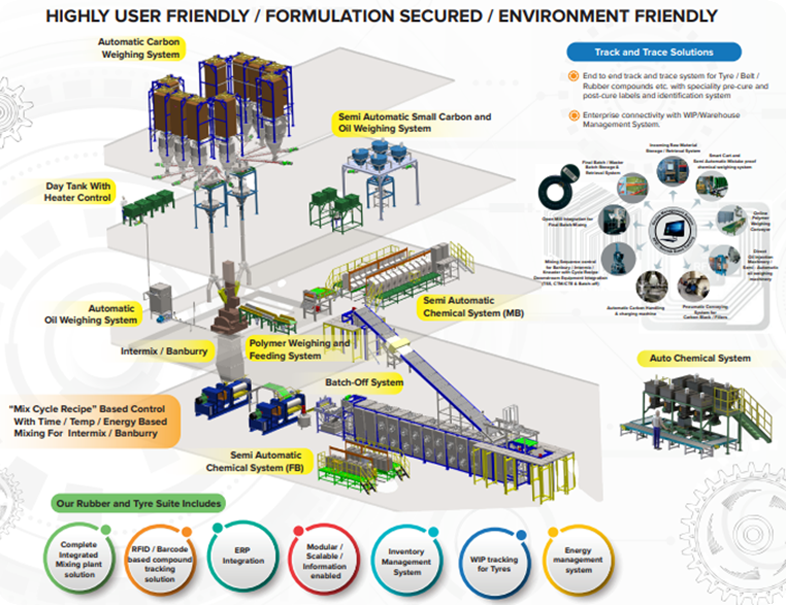

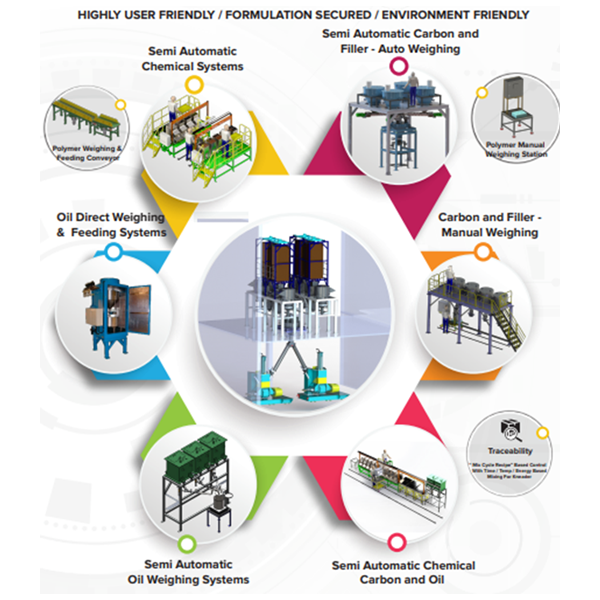

Pneumatic Conveying & Weighing Systems

-

Recommended for high-consumption applications (above 1 ton/hour)

-

Ideal for plants with height constraints

-

Closed-loop, dust-free material transfer with high reliability and minimal maintenance

-

Integrated weighing using gravimetric load cell-based hoppers

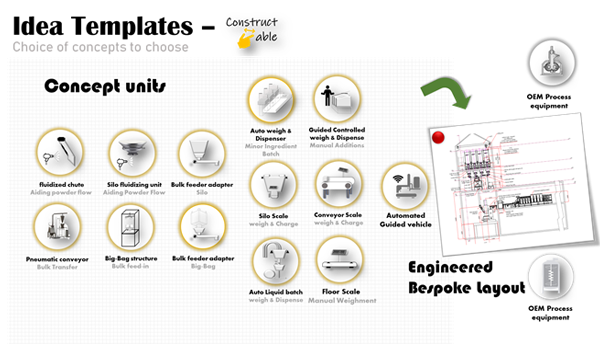

Intermediate Bins & Silos

-

Bag neck mounting arrangement

-

Flow pads, vibrators, and sensors for material movement

-

Knife Gate Valves for controlled discharge

-

MOC: Available in Mild Steel (MS) or Stainless Steel (SS)

Screw Feeders

-

Polyurethane (PU) flights to prevent material sticking

-

Modular design for easy replacement and low wear & tear

-

Maintenance-friendly construction

Weigh Hoppers

-

Gravimetric design with high-accuracy load cells

-

Fluidization chute for smooth discharge to the mixer

Oil Dosing System

-

Day tank and injection unit setup

-

Optional heater for oils depending on viscosity

-

Controlled via coarse and fine valve mechanism for dosing precision

Polymer Feeding

-

Managed via weighing conveyor system

-

Buffer conveyors ensure continuous feeding

-

Barcode-based cross-check for material verification

Small Chemical Weighing System

-

Semi-Automatic 2-tier bin system

-

Manual or barcode-assisted weighing with cross-verification

Integrated Control & Recipe Management

-

Mixer Control Systems with sequence control logic

-

Compound Management Systems covering Master Batch (MB) and Final Batch (FB)

-

Real-time output recording for batch traceability

Full suite of modules including:

-

Store Management

-

Quality Control Integration

-

Recipe Management

-

Compound History and Tracking