Automatic & Semi-Automatic Batching and Dosing Systems For Intermix, Banbury & Kneader

Weighing & Batching Systems for Tyre and Rubber Compound Manufacturing. In tyre and rubber compound manufacturing, precise ingredient dosing is essential to ensure consistent compound quality, improved process control, and reliable product performance. Our Weighing and Batching Systems are designed to meet the stringent requirements of modern compounding operations — offering high accuracy, full traceability, and intelligent automation. We provide flexible and scalable solutions tailored to your plant layout and production volume. Our systems are capable of handling fillers, carbon black, specialty chemicals, polymers, and oils — all with seamless integration.

System Capabilities – Step-by-Step Solutions

Material Handling & Feeding Systems

-

Carbon / Filler direct feeding system

-

Semi automatic carbon / filler weighing system

-

Direct oil feeding system

-

Semi automatic oil weighing system

-

Automatic chemical weighing system

-

Semi automatic chemical weighing system

-

Polymer weighing and feeding system

Automation & Integration

-

Store management system

-

Quality Management System (QMS)

-

Recipe Management System (RMS – MB/FB/DFB)

-

Cross verification system

-

Output recording system

Mixing & Processing Control

-

Mixer sequence control

-

Mill control system

-

Mill to mill conveyor / Bucket elevator

-

Batch-off control system

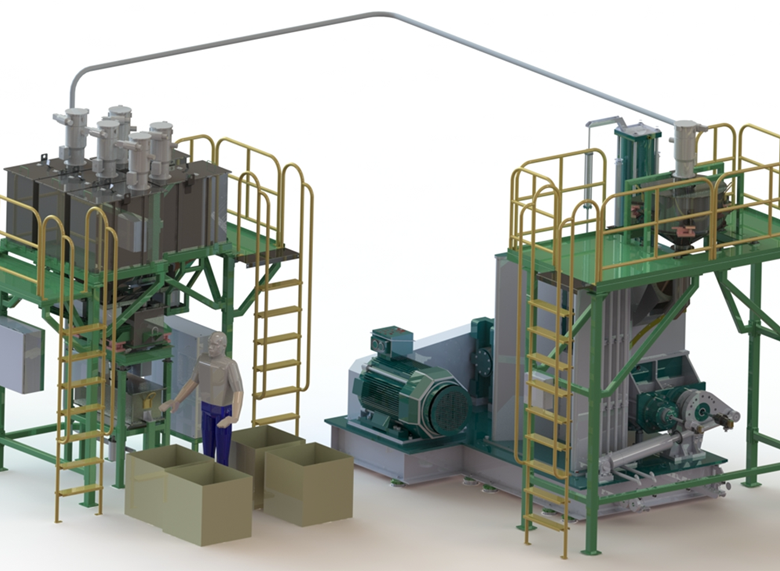

Carbon / Filler direct feeding system

System Features

-

Manual Jumbo Bag Loading

Jumbo bags are loaded manually into each station—ensuring bulk material supply with minimal handling effort.

-

Automated Weighing & Feeding

Once loaded, the system performs automatic dosing, weighing, and transfer to the mixer as per the recipe—ensuring consistency, repeatability, and minimal operator intervention.

-

Dual Weigh Hoppers + Surge Hopper

The configuration includes two weigh hoppers and a central surge hopper to allow continuous operation and optimized batching cycles.

-

Recipe-Driven Operation

The system ensures accurate blending of up to 12 different powders based on programmable recipes.

-

Direct Mixer Integration

After weighing, materials are fed directly into the mixer via a centralized discharge path, eliminating intermediate handling steps.

Carbon / Filler direct feeding system

This advanced solution is designed for automatic powder transfer from ground-level jumbo bags to elevated storage silos using a vacuum conveying system, eliminating the need for overhead bag lifting or complex infrastructure modifications. After transfer, the system performs accurate weighing and feeds the powder directly into a mixer or compounding line.

System Features

-

Ground-Level Jumbo Bag Unloading Station

Enables easy and safe loading of powders, particularly where building height is restricted.

-

Dedicated Screw Feeders

High-efficiency vacuum transfer unit lifts powder to overhead silos, minimizing dust and product loss. Suitable for carbon black, filler powders, pigments, and similar fine materials.

-

Automated Weighing and Discharge

Each powder is dosed via screw feeders into dedicated weigh hoppers, ensuring batch accuracy as per the recipe.

-

Direct Mixer Integration

post-weighing, powders are conveyed directly into the mixer inlet, enabling fully automatic batch delivery.

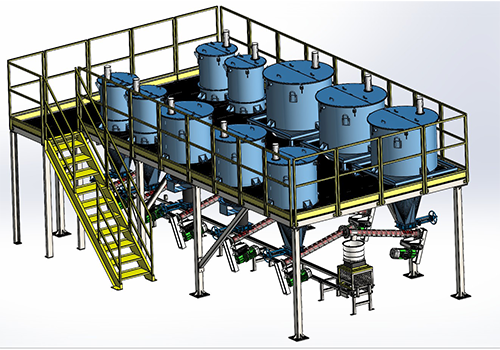

Carbon / Filler direct feeding system

This system is tailored for direct feeding of powders into a dual kneader setup, ensuring synchronized, high-precision batch delivery for demanding mixing applications like masterbatch, carbon black, or rubber compound preparation

System Features

-

Jumbo Bag Unloading Stations

Large-volume storage frames accommodate bulk powder materials, minimizing handling frequency.

-

Dedicated Screw Feeders

Each hopper is equipped with a precision screw feeder for controlled and recipe-driven dosing.

-

Independent Weighing Hoppers

Accurate, load-cell-based weighing ensures each material is batched as per formulation.

-

Automated Diverter System

Post-weighing, materials are automatically directed to the respective kneader without manual intervention.

-

Dual Discharge Lines

Twin output configuration feeds two kneaders simultaneously, supporting parallel operation or alternate batch loading.

-

Dust-Free & Efficient

The enclosed system significantly reduces powder spillage and airborne contamination.

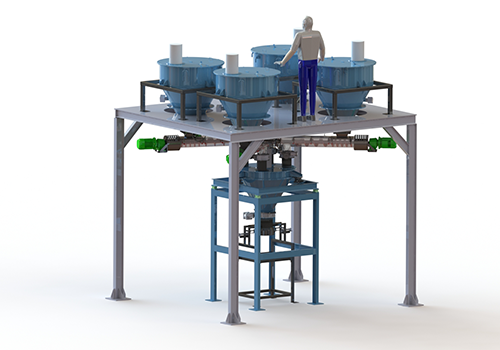

Granular direct feeding system

Optimize your material handling with our automatic granular feeding system, designed for seamless integration with kneaders. This compact system is engineered for same-floor placement, offering a highly efficient and accurate method for delivering granular materials directly to your process.

System Features

-

Kneader Compatibility

Specifically designed for optimal compatibility and direct feeding into kneaders.

-

Same-Floor Installation

Compact design allows for convenient placement on the same floor as your kneader, simplifying layout and operation.

-

Vacuum Loading

Granular materials are efficiently loaded into the system bins via vacuum transfer.

-

Recipe-Based Automatic Weighing

Materials are precisely weighed from the bins according to pre-programmed recipes, ensuring consistency and accuracy.

-

Surge Hopper with Cross-Verification

Weighed materials are transferred to a surge hopper equipped with a load cell for verifying the batch weight before feeding.

-

Direct Kneader Feeding

The system provides a direct and controlled feed of weighed materials into your kneader.

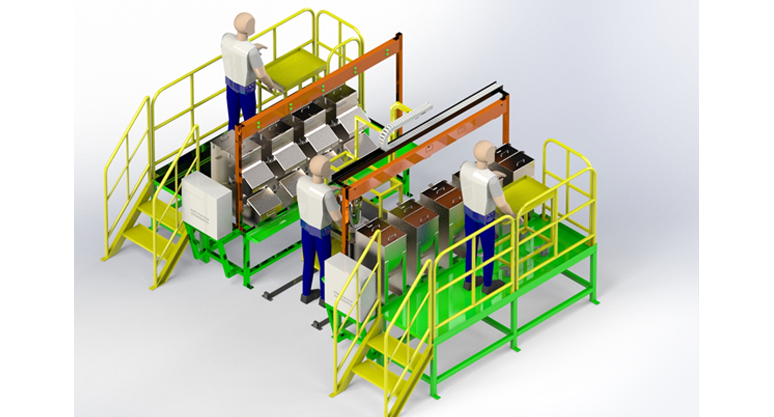

Semi automatic carbon / filler weighing system

This Semi-Automatic Carbon / Filler Powder Weighing System is engineered to ensure accurate, efficient, and recipe-driven batching of carbon and filler materials.

System Highlights

-

Manual EVA Loading

Operators are only required to manually place EVA bags into designated bowls at each station.

-

Automated Weighing

The system automatically weighs the carbon or filler powders based on pre-set recipes, ensuring consistency and accuracy.

-

Recipe-Based RGV Collection

A compact Rail Guided Vehicle (RGV) moves through each station, collecting materials precisely as per the recipe plan.

-

Optimized Workflow

Once weighing is complete, the bowls are transferred to the opposite side of the platform for further processing—streamlining material flow and reducing manual handling.

Semi automatic carbon / filler weighing system

This Semi-Automatic Powder Weighing System is designed for efficient and accurate batching of up to 8 different powders, such as carbon black, fillers, and other additives used in EVA compounding and similar processes.

System Features

-

Multiple Silo Integration

Supports up to 8 powder silos, each equipped with a dedicated screw feeder for precise material dosing.

-

Centralized Weighing Hopper

All materials are conveyed via screw feeders and combined into a single weigh hopper, ensuring accurate total batch weight as per the recipe.

-

EVA Bag Collection

Once weighed, the batch is discharged into a collection bowl or EVA bag, ready for further processing.

-

Operator-Friendly Layout

The system is semi-automatic—operators simply place the EVA bag, initiate the recipe, and the system handles the rest.

Automatic chemical weighing system

System Features

-

Integrated Storage & Feeding

Equipped with chemical storage bins and compact, high-precision feeders for consistent material flow.

-

Accurate Weighing Module

Advanced weighing units ensure recipe accuracy with a precision of ±3 to 5 grams.

-

Fast & Efficient Delivery

The system delivers each recipe within 2 to 3 minutes, optimizing productivity without compromising quality.

-

Material Handling Versatility

Capable of dispensing a variety of materials including powders, pellets, flakes, and pastilles.

-

Automated Transfer Line

A built-in conveyor system seamlessly moves containers between stations, enabling continuous operation and reduced manual handling.

Semi automatic chemical weighing system

System Features

-

Manual Weighing

Operators perform the weighing process directly using a calibrated weigh scale.

-

Poke-Yoke Error Proofing

The system incorporates a poke-yoke mechanism on both the loading and weighing sides to guide the operator and prevent mistakes, ensuring the correct chemical is weighed at the right step.

-

Versatile Chemical Handling

Suitable for accurately weighing different types of chemicals.

-

Integrated Weigh Scale

A reliable weigh scale is integrated into the system for precise measurements.

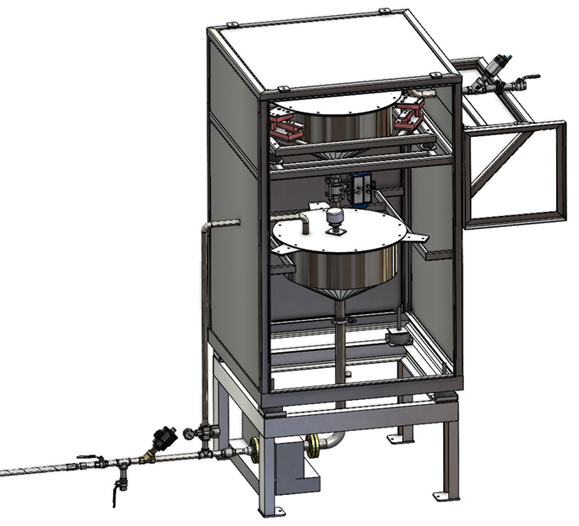

Direct oil feeding system

System Features

-

Multi-Oil Handling Capability

Supports up to 9 types of process oils, allowing flexible and recipe-driven formulation with minimal manual intervention.

-

Integrated Heating System

Oil line is equipped with temperature-controlled heating (If necessary) to reduce oil viscosity and improve flowability, ensuring smooth and consistent transfer.

-

Dual-Tank Configuration

Includes a dedicated weigh hopper for precise measurement and a surge hopper for storing and stabilizing a complete batch prior to injection.

-

High-Pressure Oil Injection

Delivers oil directly to the mixer at pressures up to 20 bar, enabling quick and uniform dispersion into the kneader.

-

Automated Weighing System

Weighing is performed based on recipe formulations via high-accuracy load cells, ensuring consistency and traceability.

-

Air Purging Unit

A built-in air purge system clears residual oil from the pipeline after each batch, preventing contamination and ensuring accurate dosing in subsequent cycles.

-

Fully Enclosed System

The design minimizes oil spillage, enhances operator safety, and ensures a clean working environment.

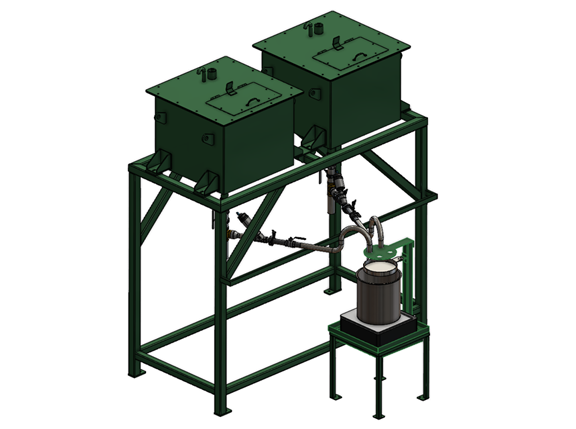

Semi automatic oil weighing system

System Features

-

Integrated Oil Storage Tanks

The system includes dedicated oil storage tanks mounted on a sturdy platform, enabling gravity-fed oil transfer to the weighing bowl.

-

Precision Flow Control Valve

Equipped with an automated control valve, the system ensures gradual and accurate oil flow, minimizing overshoot during final weight adjustment.

-

Weighing Bowl on Digital Scale

A high-accuracy load cell-based weighing scale with a mounted bowl ensures reliable batch measurement according to formulation requirements.

-

Operator-Friendly Design

Designed for Semi-Automatic operation, the system supports manual start/stop control while maintaining batch-to-batch consistency.

-

Compact & Space-Efficient

Its small footprint makes it ideal for retrofitting in existing production lines or small-batch applications.

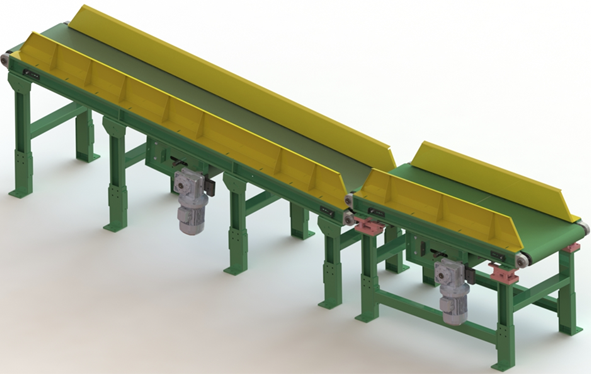

Polymer weighing and feeding system

This system is purpose-built for automated weighing and feeding of polymer bales into a kneader or internal mixer. It ensures precise recipe-based dosing, reduced manual handling, and seamless integration into modern rubber compounding processes.

System Features

-

Weighing Conveyor with Load Cells

Equipped with a precision belt conveyor mounted on load cells, this module ensures accurate polymer bale weighing as per the recipe requirement.

-

Intermediate Holding Conveyor

It positioned after the weighing conveyor to hold polymer bales and FB chemicals, maintaining correct sequence and spacing for downstream feeding.

-

Feeding Conveyor to Mixer

A dedicated feeding conveyor transfers the weighed materials—either directly from the weighing conveyor or from the intermediate conveyors—to the mixer in exact formulation order.

-

Recipe-Based Sequential Operation

Fully automated control logic ensures materials are loaded and weighed in strict recipe order, enabling consistent compound quality.

-

Heavy-Duty Construction

Built to handle large, dense polymer bales and chemical bags, the conveyors are engineered for durability and minimal maintenance.

-

Seamless Integration

Easily integrates with batch control systems or SCADA for full traceability, recipe management, and process reporting.