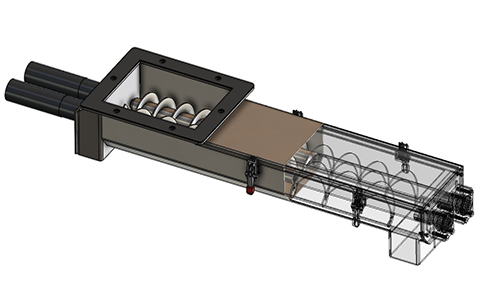

We specialize in designing and manufacturing high-quality screw feeders (available in single or dual screw configurations) to handle a wide range of powder materials efficiently and accurately. Whether you’re working with chemical powders (such as calcium carbonate, sulphur, carbon black, barium, talcum, silica), industrial powders (like cement, fly ash), food powders (like flour, starch, sugar), or our screw feeders are built to deliver consistent and smooth material flow.

Key Features :

From fine powders to abrasive materials, our screw feeders offer reliable performance across food, chemical, pharmaceutical, and industrial sectors.

-

PU Flights

We use polyurethane flights to maintain an even pitch, which ensures a constant and controlled feed rate without clogging.

-

Custom Lengths

Screw feeders are available in sizes up to 5 meters, tailored to fit your process and layout.

-

Speed Control

Each unit comes with a Variable Frequency Drive (VFD) to precisely control the screw speed, giving you maximum flexibility and efficiency.

-

Robust Design

Engineered for long-lasting performance and minimal maintenance.