As per the available Lay out (space )

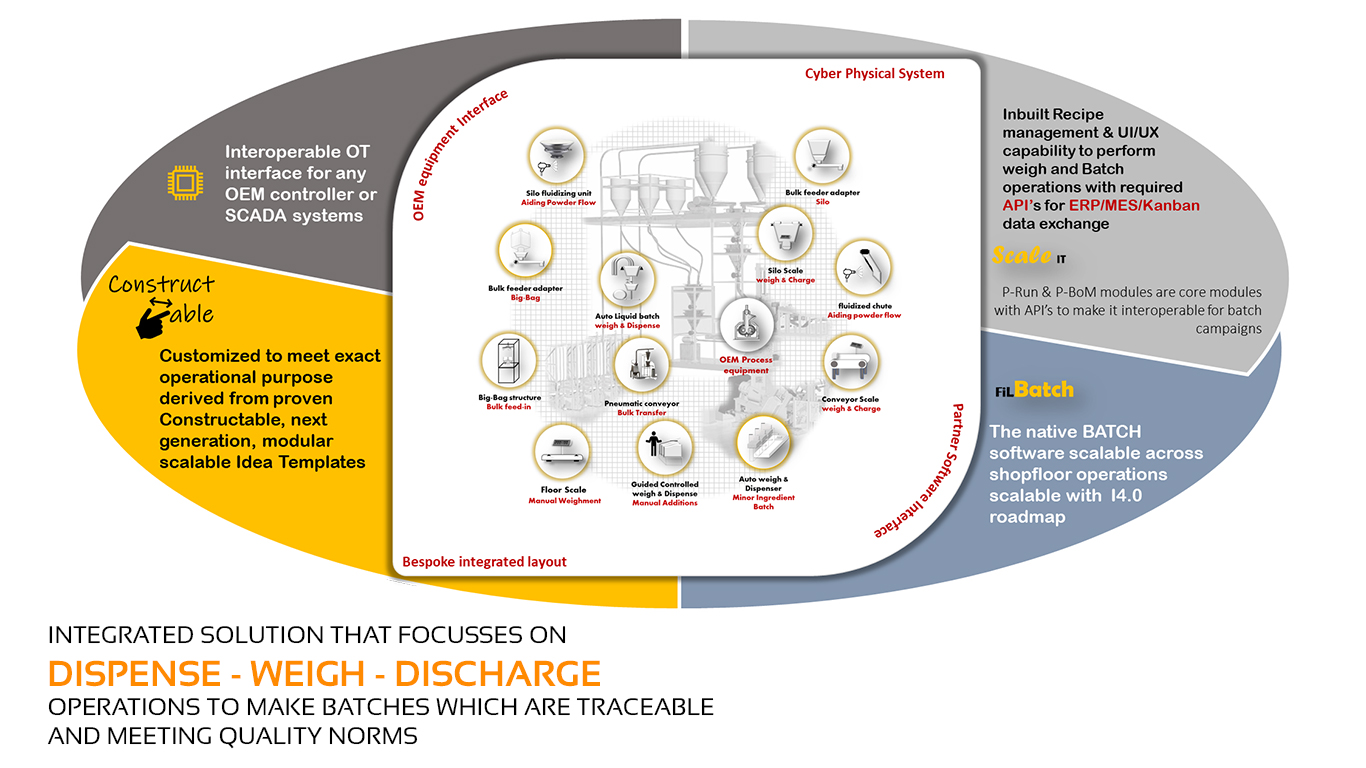

FIL-Batch – Factory Infrastructure Logistic for Batch system

- Home

- FIL-Batch – Factory Infrastructure Logistic for Batch system

Addresses the Multi ingredients (BoM) measured and Feed in sequence under specific process conditions to form a Batch number of times as per the production process requirement.

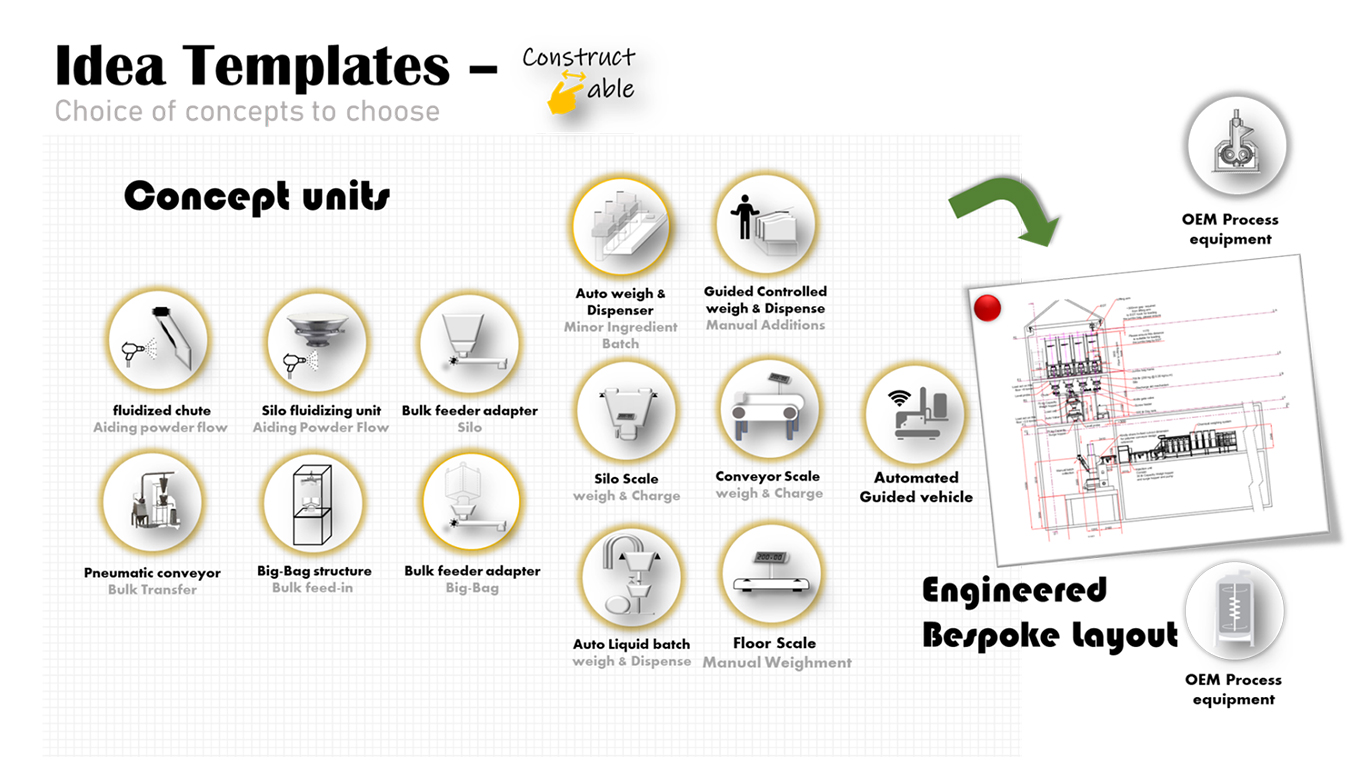

OUR Bespoke constructable templates has specific designs for Weigh scales, Dispensers and transporters which can be engineered to make tailer made systems

-

-

Meeting the Capacity (mixer capacity)

-

Meeting the desired Cycle time (Process efficiency)

The designs are carefully crafted to ensure proper handling of the material for its flowability, smooth transferring, Interoperable with controlled Environment systems and Safe ease of operations.

- Material of Construction based on the Material properties and Working conditions

- Usage of Material Flow Aids

- Ergonomic designs for ease of manual operations and maintenance friendly

- Modular and Scalable make additions or make layout changes with optimum time and money.

- The bespoke mechanization value added with Operation Technology (PLC/SCADA) for sequential controls and IT enablement .

- Easy to use recipe management system to formulate and run your Batch Process through embedded Application with open Interfaces

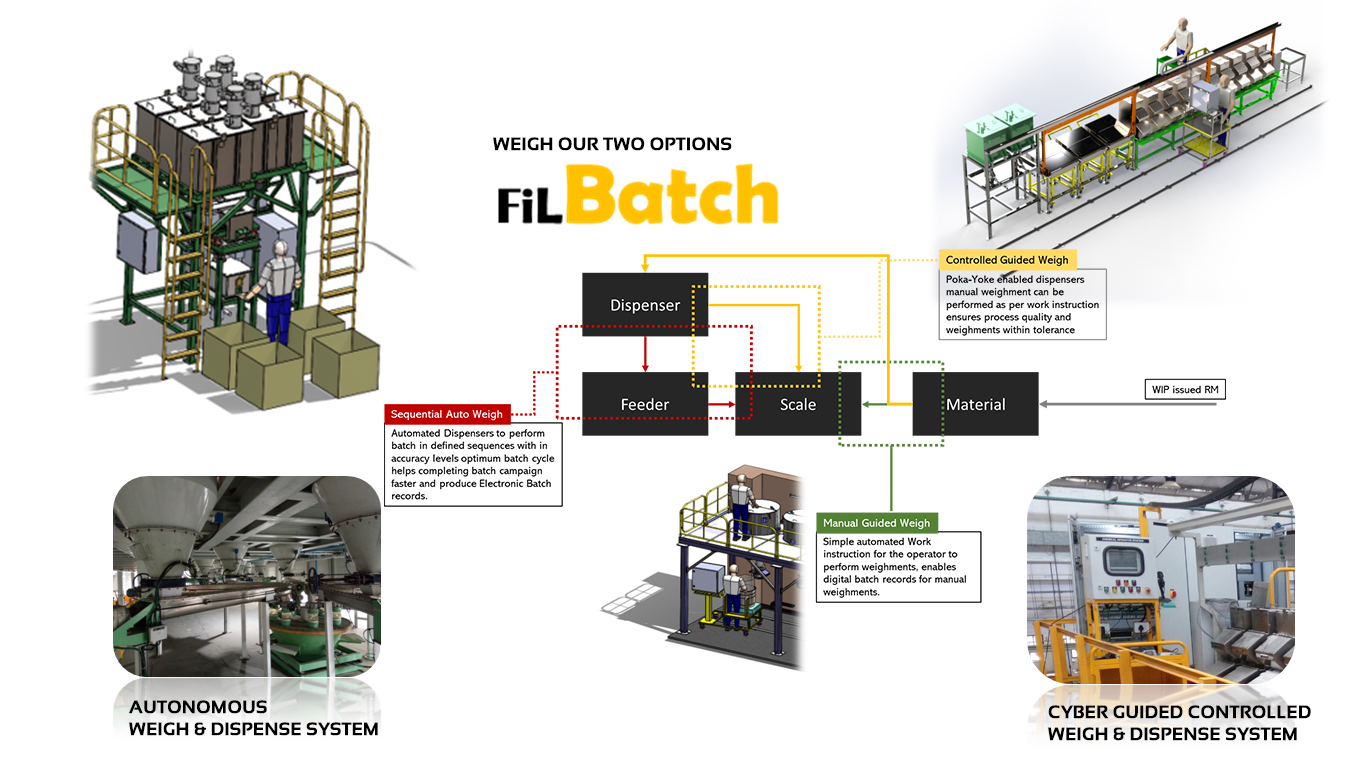

Cyber Guided Controlled Weigh & Dispensing

-

Recommended for Multi ingredient Small Size Batches

-

Both For Powders and Liquids (oil/Resin )

-

Economic Version suites SME’s focussing fool proof production of Minor ingredients

- Simple to follow Guiding messages and Audio-visual indications requires no special skills for the operators

- Poka-Yoke interlocks enabled for each manual steps and weighment accuracy and Loading Day stock (replenishments) ensured

- Electronic Batch records can be coded, reported with actual data which can be printed, used in KANBAN cards.

- All Traceability Events electronically recorded for each batch which can be tracked back to RM batch Lot.

- Flexible Recipe Management system the user can create unlimited Recipes to perform.

- Requisite API’s to interface with Order management and Batch campaign (Planning) systems as per the adopted work flow.

- Built in ABORT Sequences as per the best practices

- Quality management, Supermarket (WIP Stores) inventory management can be interfaced.

Autonomous Weigh & Dispensing

For Minor Ingredients

-

Recommended for Multi ingredient Small Size Batches

-

Small Size Batches but faster and higher throughput requirements of various recipe changeovers

- Loading the carrier (eva bags) and start the batch will be suffices.

- Poka-Yoke interlocks enabled when any manual steps and weighment accuracy and Loading Day stock (replenishments) ensured

- Electronic Batch records can be coded, reported with actual data which can be printed, used in KANBAN cards.

- All Traceability Events electronically recorded for each batch which can be tracked back to RM batch Lot.

- Flexible Recipe Management system the user can create unlimited Recipes to perform.

- Requisite API’s to interface with Order management and Batch campaign (Planning) systems as per the adopted work flow.

- Built in ABORT Sequences as per the best practices

- Quality management, Supermarket (WIP Stores) inventory management can be interfaced.

Autonomous Weigh & Dispensing

for Bulk Solids

-

Recommended for Bulk solids ingredient

-

Small Size Batches but faster and higher throughput requirements of various recipe changeovers.

- Simple to monitor current process and Alerts messages and Audio visual indications requires no special skills for the operators.

- Poka-Yoke interlocks enabled for each manual steps on loading unloading and organising of RM’s and produced Batches where weighment accuracy and Loading Day stock (replenishments) ensured.

- Electronic Batch records can be coded, reported with actual data which can be printed, can support KANBAN.

- All Traceability Events electronically recorded for each batch which can be tracked back to RM batch Lot.

- Flexible Recipe Management system the user can create unlimited Recipes to perform.

- Requisite API’s to interface with Order management and Batch campaign (Planning) systems as per the adopted work flow.

- Built in ABORT Sequences as per the best practices

- Quality management, Supermarket (WIP Stores) inventory management can be interfaced.

Autonomous Weigh & Dispensing

for Liquids

-

Recommended for Liquid ingredient

-

Small Size Batches but faster and higher throughput requirements of various recipe changeovers.

- Multi liquids dispensed for weighments automatic.

- Intermediate Charge vessel with Injection pump for auto material discharge to process equipment in sequence.

- Poka-Yoke interlocks enabled for each manual steps on loading unloading and organising of RM’s and produced Batches where weighment accuracy and Loading Day stock (replenishments) ensured.

- Electronic Batch records can be coded, reported with actual data which can be printed, can support KANBAN.

- All Traceability Events electronically recorded for each batch which can be tracked back to RM batch Lot.

- Flexible Recipe Management system the user can create unlimited Recipes to perform.

- Requisite API’s to interface with Order management and Batch campaign (Planning) systems as per the adopted work flow.

- Built in ABORT Sequences as per the best practices

- Quality management, Supermarket (WIP Stores) inventory management can be interfaced.

Material Transfer Systems

for Solids

-

Choice of mechanised and Pneumatic based (powder) and for liquid dispensing pumps based on the space and economic scale of value.

-

Bespoke designs suitable to handle different packages like Big bags, Paper bags, Sacks, barrels etc., s.

- Mobility/fixed guiding system integrated

- Indication for material replenishments

- Poka-Yoke interlocks enabled for each manual steps on loading unloading and organising of RM’s and produced Batches where weighment accuracy and Loading Day stock (replenishments) ensured.

- KANBAN supported identification system for material loading process

- All Traceability Events electronically recorded for each batch which can be tracked back to RM batch Lot.

- Requisite API’s to interface with Order management and Batch campaign (Planning) systems as per the adopted work flow.

- Built in ABORT Sequences as per the best practices

- Quality management, Supermarket (WIP Stores) inventory management can be interfaced.

Design and Construction

- Bespoke designs tailer made to your adopted Production practices, Layout, expected capacity and material properties.

- Choice of Material of Constructions

- Carefully crafted Designs, Precision fabricated and assembled inhouse with quality on time delivery.

- Modular scalable arrangements can be expanded as when needed and be re arranged with minimal efforts.

- Unique J Bins single Tier/Two tier of different capacities to hold day stocks and designed for ease of flow maintaining FIFO.

- Ergonomic Physical arrangements for operator convenience and safety. flow maintaining FIFO.

- Modular Plug and play Control Architecture.

- Optional Index Trolley to perform repeat ingredient weighment to produce multi batch in single cycle.

- Optional Dust collection system to keep the production environment dust free.

- Optional Loading trolley for convenience fatigue free loading.

Digital Features

- Powerful Recipe Management System to create unlimited Recipe formulations, or download master recipe BoM from Enterprise system (option)

- Basic RMS independently work with the physical system to produce and track Batches and update Batch reports, Consumption and production.

- Scalable to interoperate with other WorkCentre’s to make the batch campaigns when interfaced.

- BARCODE. RFID technology can be incorporated as required

- IIoT, Mobility enabled (option)

- Scalable to Plant wide MES

- Scalable to Quality management SPC system